3D Printed Wind Turbine (11/28/2017)

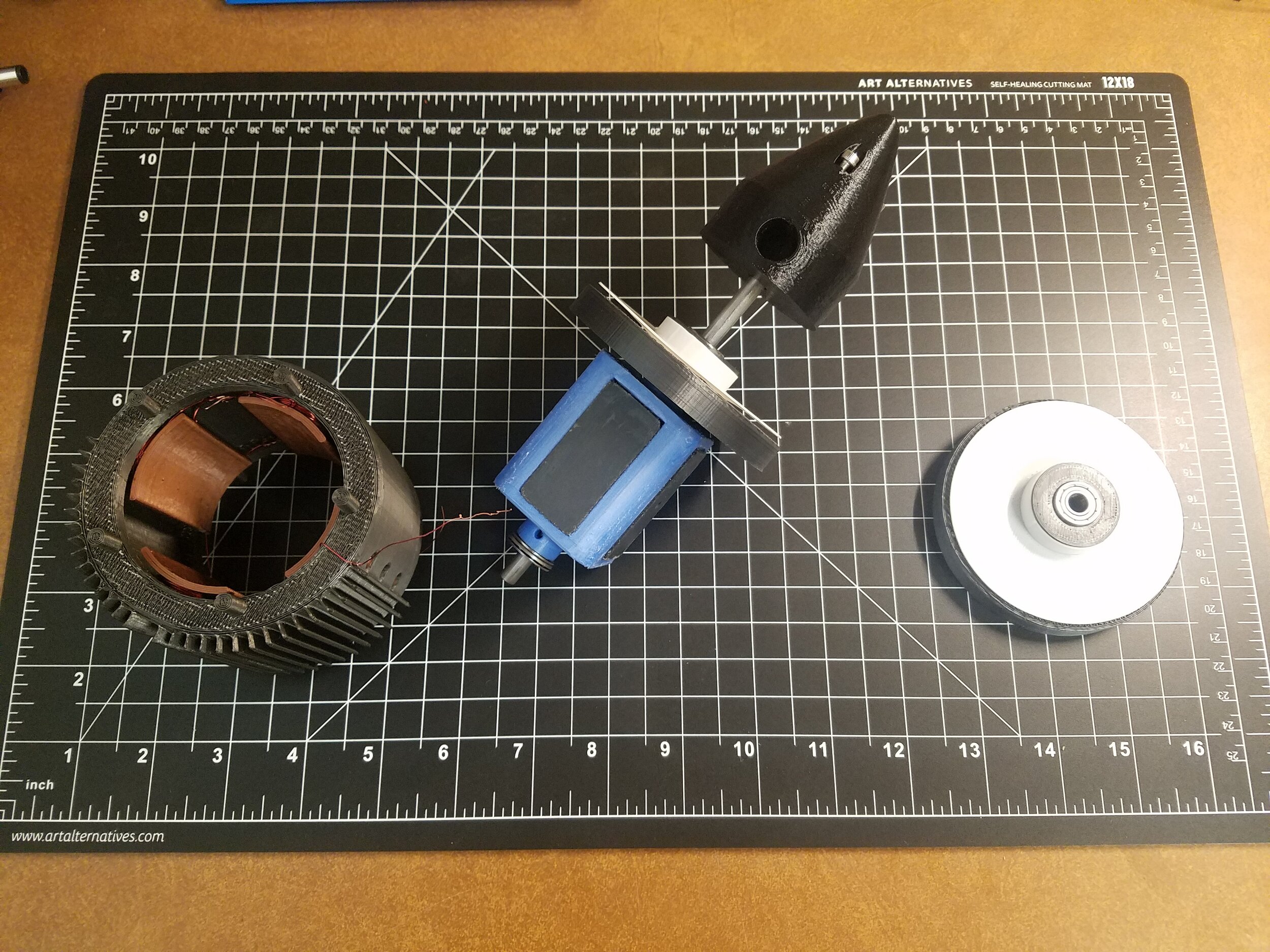

A section view of the generator

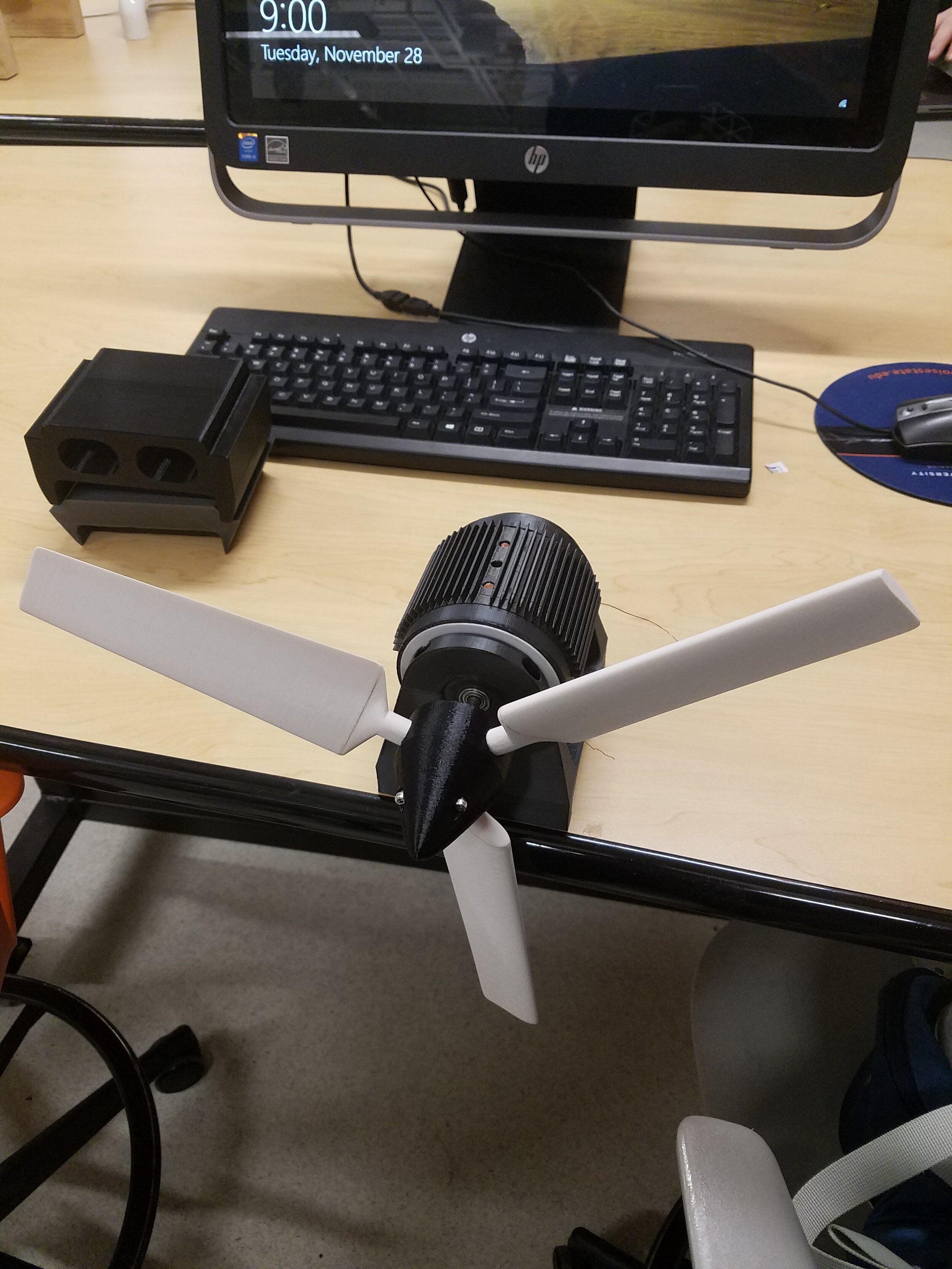

The airfoils for the wind turbine. In class we determined that 3 blades was the optimal number

In Boise State’s Freshman Year Intro to Engineering class, students are required to design and build a generator, and then make it into a wind turbine. How exactly to do it is left to the students, but some materials like pegboard, cardboard, wood, and manila folders are provided for making everything. The instructor also provided four ceramic magnets, magnet wire, and a 1/4” steel shaft. After making some prototypes with the materials provided, and doing tests to figure out the best way to wind the wire and the idea coil order, I decided to design and 3D print everything from PLA. After all, what good is having a 3D printer if you don’t use it?

Starting with the generator, I decided to keep use the same shaft, magnets, and magnet wire that were provided, but design the rest of the generator around those parts.

I wanted the shaft to spin as freely as possible, so ball bearings were the clear choice for radial constraint. The turbine would eventually be put in a wind tunnel for testing though, so I realized I also needed to constrain the shaft axially. I settled on opposing thrust bearings sandwiched between the rotor and the stator’s end caps. With bearings and placement in mind, I designed the rotor. The only two real goals here were to make it as small as possible to reduce the inertia, and to fit all four magnets. I then added a hub on each side for the thrust bearings to mate with, and so there was a place to use set screws to hold it onto the shaft.

For the stator, I decided to design it in parts. This would make the generator easier to both assemble and print. I started with the coil placement. I used four coils for simplicity, but eight could have fit if I moved things around a bit. After making sure the coils had parts to attach to and checking that the rotor would clear them while spinning, I designed the stator’s main body to hold the coils and their retainers in place. After that, I designed end caps for the stator and added space for the ball bearings to go in.

With the generator’s main parts designed, I printed the parts to make sure everything fit together so I could fix any issues. I already had the bearings I needed on hand, so I didn’t need to order them and wait for delivery. There weren’t any problems with fits or tolerances, so I went ahead and designed a base/stand. In the wind tunnel, the turbine would have to fit on a 2x4, so I designed it to fit that. During a test fir in the wind tunnel, I realized the turbine needed to be raised up, so I ended up making a few spacers to give it some extra height. As a last minute thought, I printed some vibration dampers out of TPE to go between the stator’s end caps and the base in case anything was slightly out of balance.

To make the airfoils and a nose to hold them in place, I was pretty out of my comfort zone. I’ve never really done anything involving airfoils before this, so I did a lot of research to figure out how to design airfoils, what airfoil profiles wind turbines used, and why they used those profiles. It was definitely more information than I could process in the time I had, but I still decided to give designing airfoils a try. In the end I settled on a NACA 6725 profile at the base of the blade, and a NACA 6525 profile at the tip, with a 15° twist to account for the higher tip velocity. The blades are 150mm long, since that’s pretty close to the maximum height my printer can make and I didn’t want to make them in multiple parts. I printed them in some ASA I had left over from a UV resistant version of the Gyrocup because it has really good layer adhesion, and this really paid off. The blades were sanded to be smooth, and after inspecting them for any defects I installed them on the generator. Impressively, while I was carrying it to class the blades started spinning just from me walking.

On the test day, the turbine generated nearly 91mW at 1.65 volts in a wind speed of 16m/sec. It didn’t show any signs of breaking, and the wind tunnel was only at 50% speed, so the instructor said we could see how much wind it could withstand. Ultimately, at a wind speed of 35m/sec one of the blades delaminated along the layer lines, and the whole generator jumped around, breaking the other blades due to the unbalanced forces. None of the parts inside the generator broke though, and with a new set of blades everything worked just as well as before.